Understanding Common Glow-Worm Boiler Fault Codes

Common Glow Worm fault codes

Glow-worm is a leading manufacturer of heating systems, notable for its superior British engineering and design. Like many other boiler manufacturers, Glow-worm boilers are equipped with a built-in fault code system. This system helps users identify when their boiler is not functioning correctly. It's critical to note that these error codes are not solutions themselves but rather signposts indicating the area of the problem. Remember, any work involving a gas appliance should be performed by a registered Gas Safe engineer. Handling such issues yourself can not only cause further damage to the boiler but may also be hazardous.

Let's take a closer look at some commonly occurring Glow-worm boiler fault codes:

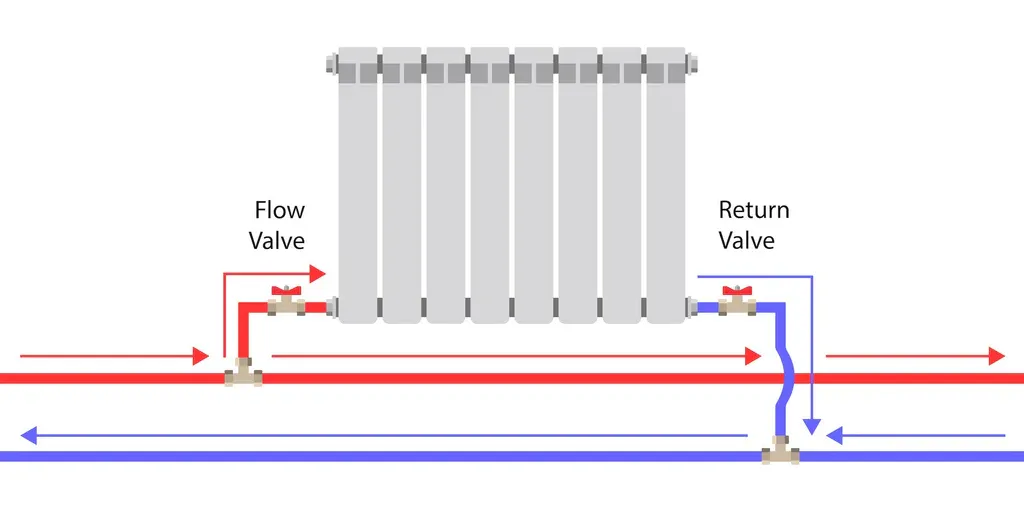

1. **F1 – Low Water Pressure:** This indicates that the boiler has detected low pressure in your system and may not function correctly. You can usually rectify this yourself by re-pressurising your heating system.

2. **F4 – Ignition Fault:** This suggests that the boiler is trying to ignite but is unsuccessful. This could be due to a number of reasons, including an issue with the gas supply or a fault with the ignition leads.

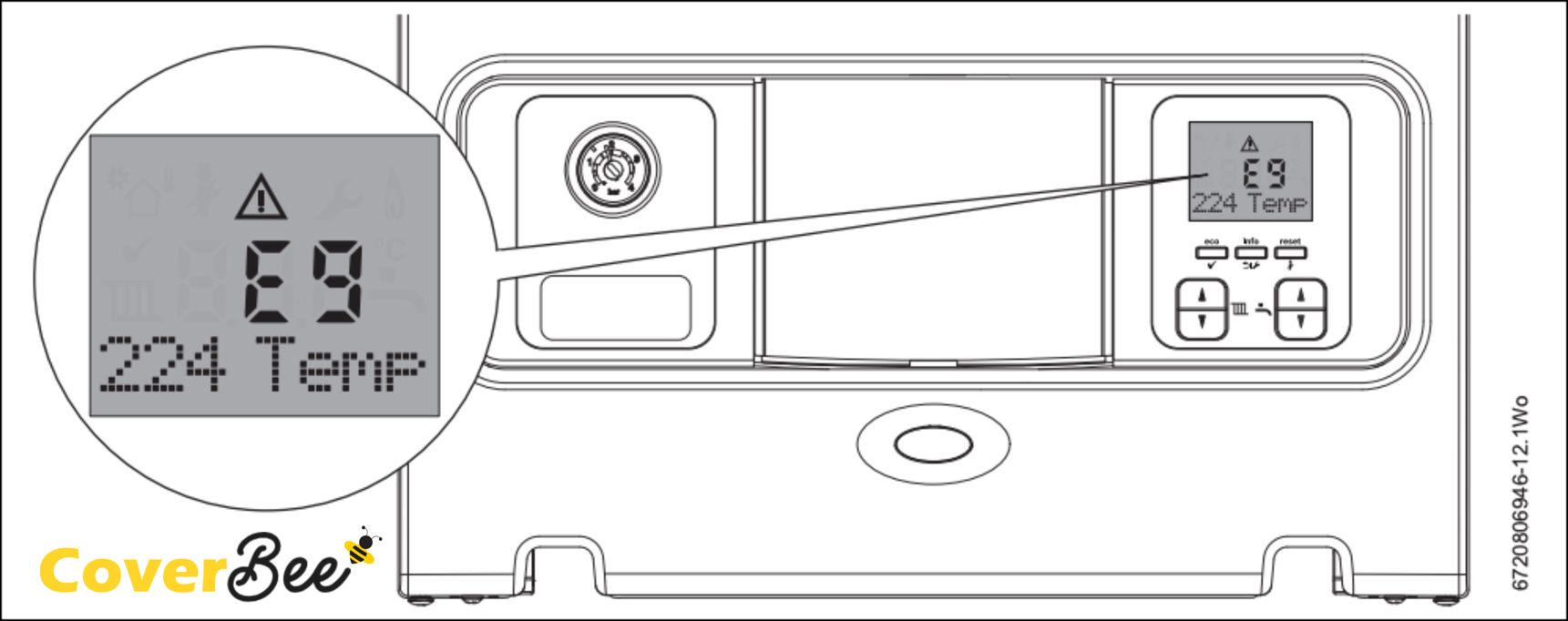

3. **F5 – Overheating Fault (Overheat Temperature Exceeded):** Should your boiler overheat, it will shut itself down to avoid any lasting damage and show this error code.

4. **F9 – Uncontrolled Flame:** This fault is serious and points to the fact that the boiler flame is out of control. It can lead to severe damages and is marked as potentially dangerous.

5. **F22 – Dry Fire:** This indicates that the boiler has run dry, signifying low water pressures or a lack of water.

There are also less common Glow-worm boiler fault codes that might appear:

6. **F2 – Flame Loss:** This code is displayed when your boiler loses flame during operation. This can occur for reasons such as a fluctuation in gas pressure.

7. **F10 – Loss of Flame Signal:** This indicates a problem with the flame detection probe; the boiler can't identify whether a flame is present. It's the flame sensing electrode's duty to make sure the flame is consistent and safe.

8. **F11 – Temperature Sensor Fault:** This means the printed circuit board (PCB) cannot identify the difference in resistance on the Thermistor or Temperature Sensor, posing a threat to the boiler's regular and safe operation.

9. **F28 – Ignition Failure:** If your boiler is unable to ignite, it will display this fault code. This could be due to incorrect gas valve settings, a disconnected ignition, or an erroneous flue.

10. **F61, F62, F63, F64, F65, and F67 – Electronic Faults:** These fault codes indicate various electronic faults, possibly related to the PCB. In this case, an engineer will often need to replace it.

It's essential to take boiler fault codes seriously. If you notice a fault code on your Glow-worm boiler, turn off the boiler and immediately get in touch with a Gas Safe engineer. Dismissing these codes could lead to severe issues, causing the boiler to completely break down, which can be more expensive to rectify, or more significantly, it may pose a potential risk to your safety.

In addition to recognising these error codes, there are other ways to identify potential boiler problems. If you notice unusual noises, leakages, the boiler switching itself off frequently, or an unexpected rise in energy bills, these might also suggest underlying boiler issues.

Regular professional servicing and maintenance are the best ways to keep your Glow-worm boiler in optimal working condition. During these checks, minor problems can be identified before they escalate into significant issues, often at a much lower cost than emergency breakdown services. It also ensures the safe operation of your boiler, potentially prolongs its lifespan, and helps to maintain the efficiency of the unit.

While this guide can help homeowners understand the issues their Glow-worm boiler might be encountering, it should never replace the role of a Gas Safe registered engineer. These professionals have the proper training and certification to safely and effectively carry out boiler repairs, so always involve them as soon as a fault occurs or an error code is displayed. Your safety should be your number one priority, and taking a DIY approach with gas appliances puts this at risk.

Bumble Group Limited

The Unicorn

Main Street

Carlton

WF3 3RW

Company reg 14984774

© 2022 Bumble Group Limited

CONTACT US

0330 533 0340

Customer.services@coverbee.co.uk

CoverBee boiler plans are a home emergency service contract and not a form of insurance.

Repair requests

To prevent works on existing issues present before the plan was taken out, you will be unable to request a repair within the 1st 14 days on all our plans.

If you require a repair within the 1st 14 days of you plan start date, you can still contact us,

we will then supply you with a quotation for one of our approved engineers to carry out a one off repair.

After you have purchased your plan, we may contact you to arrange for one of our approved engineers to carry out your boiler health check. Our engineer will inspect your boiler and heating system (if included) to ensure it is working safely and confirm it meets the requirements of contract. If you report a problem with your boiler or heating before the health check has been carried out, we will still send an engineer, but your boiler must pass the boiler health check before the repair will be carried out under this plan.