Understanding Common Worcester Bosch Boiler Fault Codes

Common Worcester Bosch fault codes

Worcester Bosch boilers have gained a reputation for their reliability and efficiency. However, like any complex equipment, they can occasionally encounter faults or errors. Understanding the fault codes displayed by these boilers is essential in troubleshooting and resolving issues promptly. This article aims to provide a comprehensive understanding of some common Worcester Bosch boiler fault codes and their potential causes, as well as offering solutions to address these problems.

1. E0 and EA Fault Codes:

The E0 and EA fault codes often indicate a problem with the boiler's ignition. E0 typically refers to a failure in the ignition sequence, while EA indicates a failure to detect a flame.

Causes:

- Gas supply issues, such as low pressure or interrupted flow.

- Faulty ignition electrode or spark generator.

- Blocked flue preventing proper ventilation.

Solutions:

- Ensure the gas supply is not interrupted; check the gas meter, valves, and pipework.

- Check the ignition electrode and clean any soot or debris interfering with the spark.

- Inspect the flue for obstructions and remove any blockages carefully.

If the fault code persists after these checks, it is recommended to contact a Gas Safe registered engineer to address the issue.

2. F.22 Fault Code:

The F.22 fault code indicates a problem related to low water pressure within the boiler system.

Causes:

- Water leakage from the system, pipes, or radiators.

- A defective pressure relief valve.

- Issues with the expansion vessel, leading to a loss of pressure.

Solutions:

- Check for visible signs of water leakage throughout the system and repair any identified leaks.

- Inspect and replace the pressure relief valve if necessary.

- In cases where the expansion vessel is faulty, it may need replacement by a trained engineer.

Once the issue is resolved, it is essential to refill the system to the optimum pressure levels recommended by the manufacturer.

3. F.28 Fault Code:

The F.28 fault code indicates a lack of ignition or inadequate gas supply to the boiler.

Causes:

- Insufficient gas supply, such as a closed gas valve or depleted fuel.

- Faulty gas valve or gas pressure regulator.

- Blocked gas supply pipe or filter.

Solutions:

- Ensure there is an adequate supply of gas, and the gas valve is fully open.

- Check and clean the gas filter or replace it if necessary.

- If the problem persists, contact a qualified technician to inspect and potentially replace the gas valve or regulator.

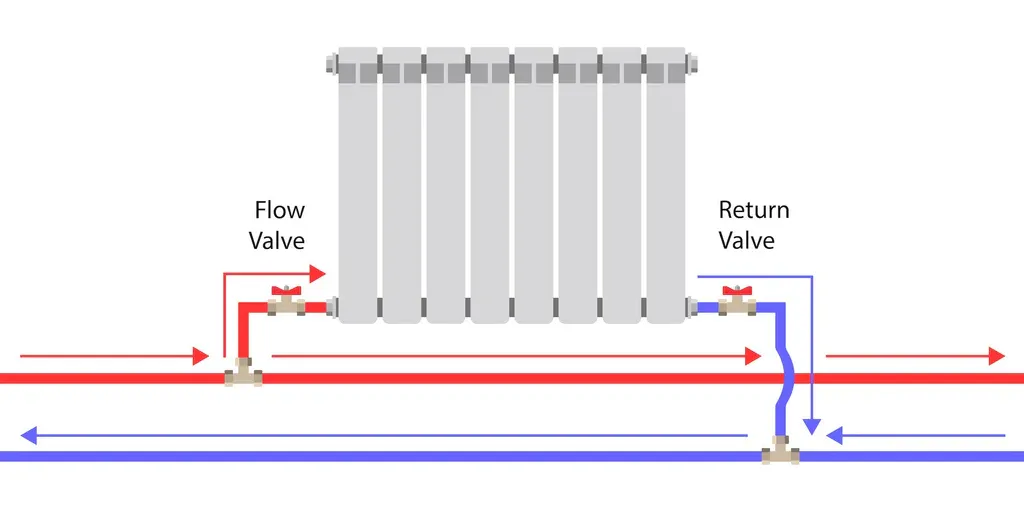

4. H1 and H3 Fault Codes:

H1 and H3 fault codes refer to a problem with the boiler's water pressure.

Causes:

- Insufficient water flow or blockage in the water supply.

- Faulty pressure sensor or pump.

- Inadequate expansion vessel in closed systems.

Solutions:

- Check the water supply valves and ensure they are open fully.

- Inspect and clean the water filter, if accessible.

- If the fault persists, the pressure sensor or pump may need inspection or replacement.

- In closed systems, the expansion vessel may require re-pressurization or potential replacement.

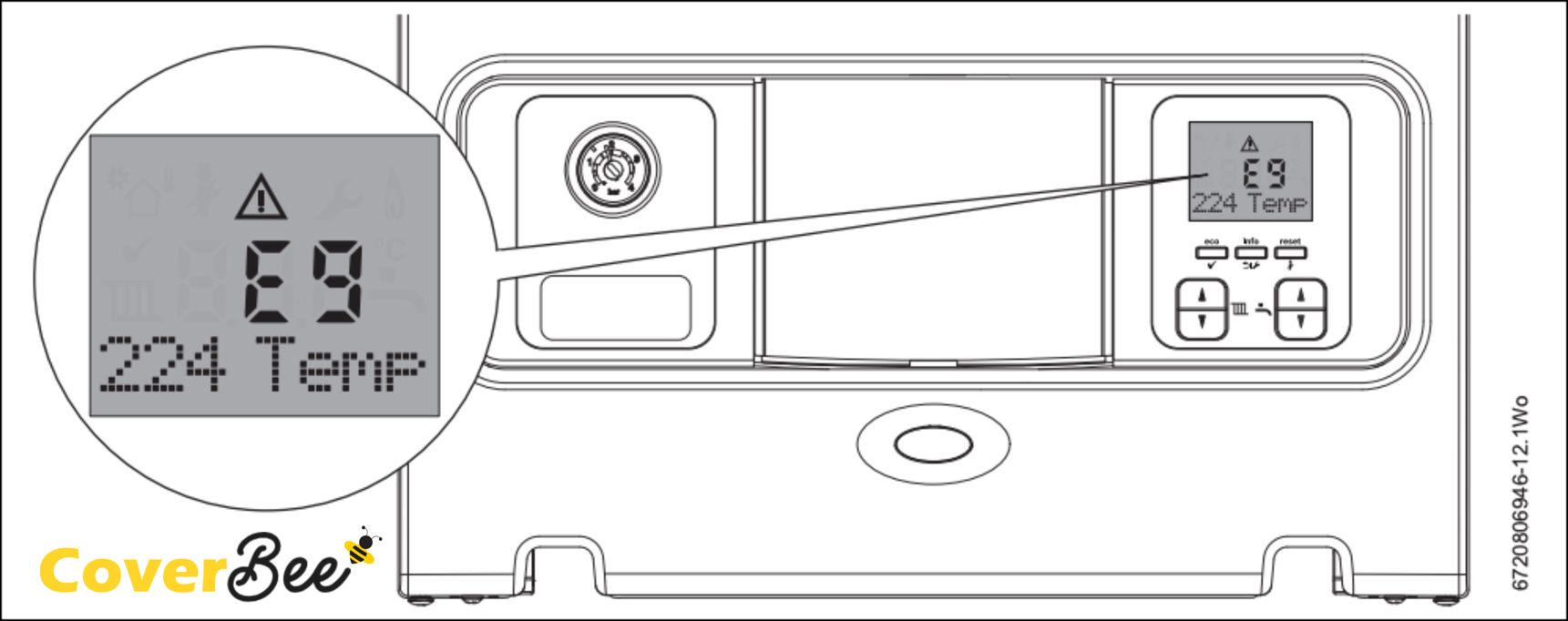

5. Other Common Fault Codes:

a) D.5 Fault Code:

The D.5 fault code indicates the flow temperature of the hot water output is too high.

Causes:

- Faulty temperature sensor.

- Problems with the control system regulating temperature.

Solutions:

- A qualified technician should inspect and, if necessary, replace the faulty temperature sensor.

- Check the control system settings for any inconsistencies and recalibrate if needed.

b) EA7 Fault Code:

The EA7 fault code suggests incorrect gas valve adjustments, resulting in an improper gas-to-air ratio.

Causes:

- Valve settings not properly configured during the installation or servicing.

- Issues with the gas valve mechanism.

Solutions:

- Contact a Gas Safe registered engineer to assess and adjust the gas valve settings.

- If the gas valve itself is determined to be faulty, a replacement may be necessary.

Conclusion:

Understanding common Worcester Bosch boiler fault codes is essential for efficient troubleshooting and effective resolution of issues. By referring to these fault codes and applying the recommended solutions, homeowners and engineers can diagnose and resolve problems more accurately, ensuring optimal performance and prolonged boiler lifespan. However, it is crucial to remember that some solutions might require the expertise of a qualified professional. Regular maintenance and servicing of Worcester Bosch boilers can also help prevent faults and ensure their continued optimal operation.

with CoverBee boiler plans we take away all the hassle when your boiler breaks down as well as providing considerable savings over using a one off repair.

You can view all our plans here.

Bumble Group Limited

The Unicorn

Main Street

Carlton

WF3 3RW

Company reg 14984774

© 2022 Bumble Group Limited

CONTACT US

0330 533 0340

Customer.services@coverbee.co.uk

CoverBee boiler plans are a home emergency service contract and not a form of insurance.

Repair requests

To prevent works on existing issues present before the plan was taken out, you will be unable to request a repair within the 1st 14 days on all our plans.

If you require a repair within the 1st 14 days of you plan start date, you can still contact us,

we will then supply you with a quotation for one of our approved engineers to carry out a one off repair.

After you have purchased your plan, we may contact you to arrange for one of our approved engineers to carry out your boiler health check. Our engineer will inspect your boiler and heating system (if included) to ensure it is working safely and confirm it meets the requirements of contract. If you report a problem with your boiler or heating before the health check has been carried out, we will still send an engineer, but your boiler must pass the boiler health check before the repair will be carried out under this plan.